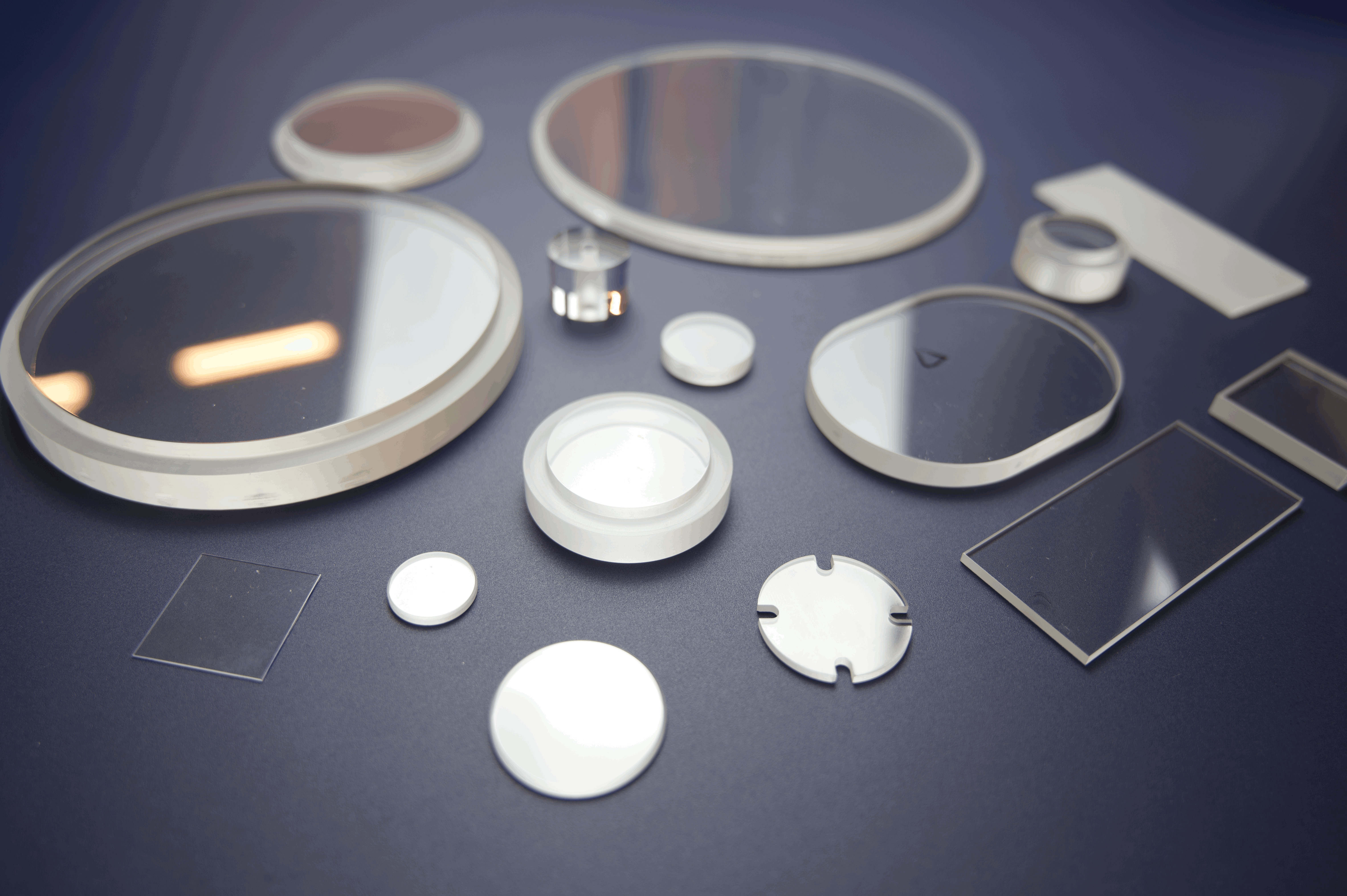

The use of single-crystal sapphire as a material for various pipes is associated with:

primarily with its physical and mechanical properties:

with high chemical inertness - for protective covers

when working in aggressive environments;

with high mechanical strength - for structural

products withstanding high pressure;

with a high melting point - for structural products,

working at high temperatures;

with high transparency - to ensure the passage

radiation in a wide range of wavelengths:

from 200 nm to 5 µm for control and measurement purposes.

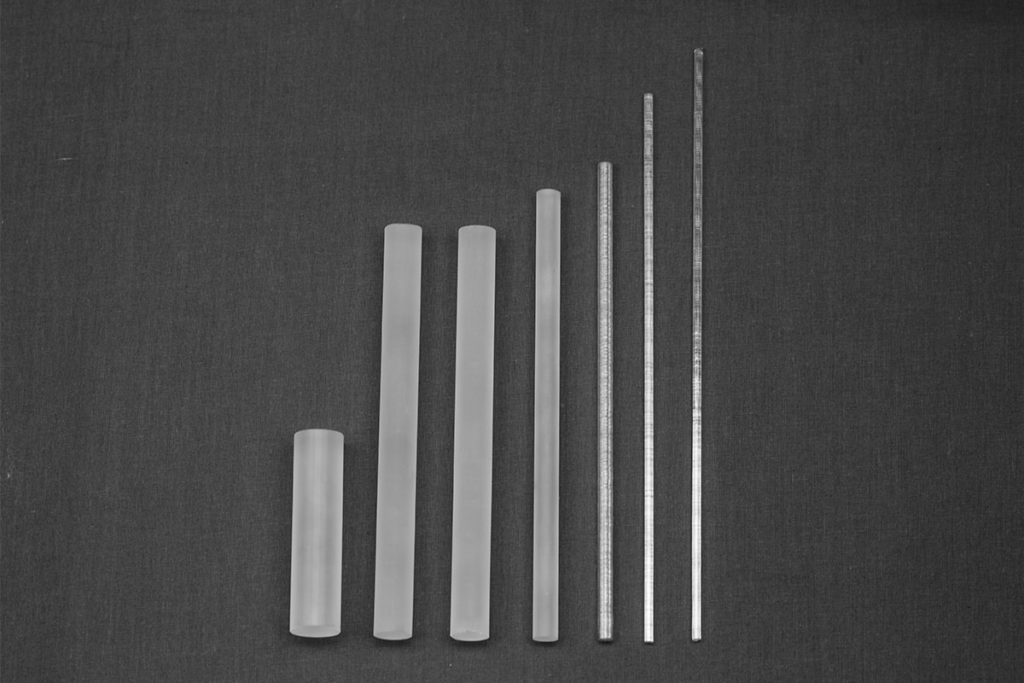

In this case, depending on the size, the pipes can be

made either by the Stepanov method (EFG):

by pulling with a pipe shaper immediately

or from ordinary single crystals:

grown by the Kyropoulos method.

Moreover, if pipes are obtained by the Stepanov method:

small diameters up to 40 mm, then from crystals obtained

the Kyropoulos method is used to make massive:

pipes with a diameter up to 250 mm:

Minimum internal pipe diameter:

grown by the Stepanov method is about 0.8 mm.